Advance ductule, Pipe Shed, grout pipe for tunnel excavation

1. Simple description:

The advanced small conduit is a process method in the process of tunnel excavation. It is mainly used in the weak broken zone

with short self-stabilization time, the shallow buried section, the partial pressure section at the entrance, the sand layer section,

the sand and pebble section, the fault broken zone and other sections. pre-support.

2. Grade:

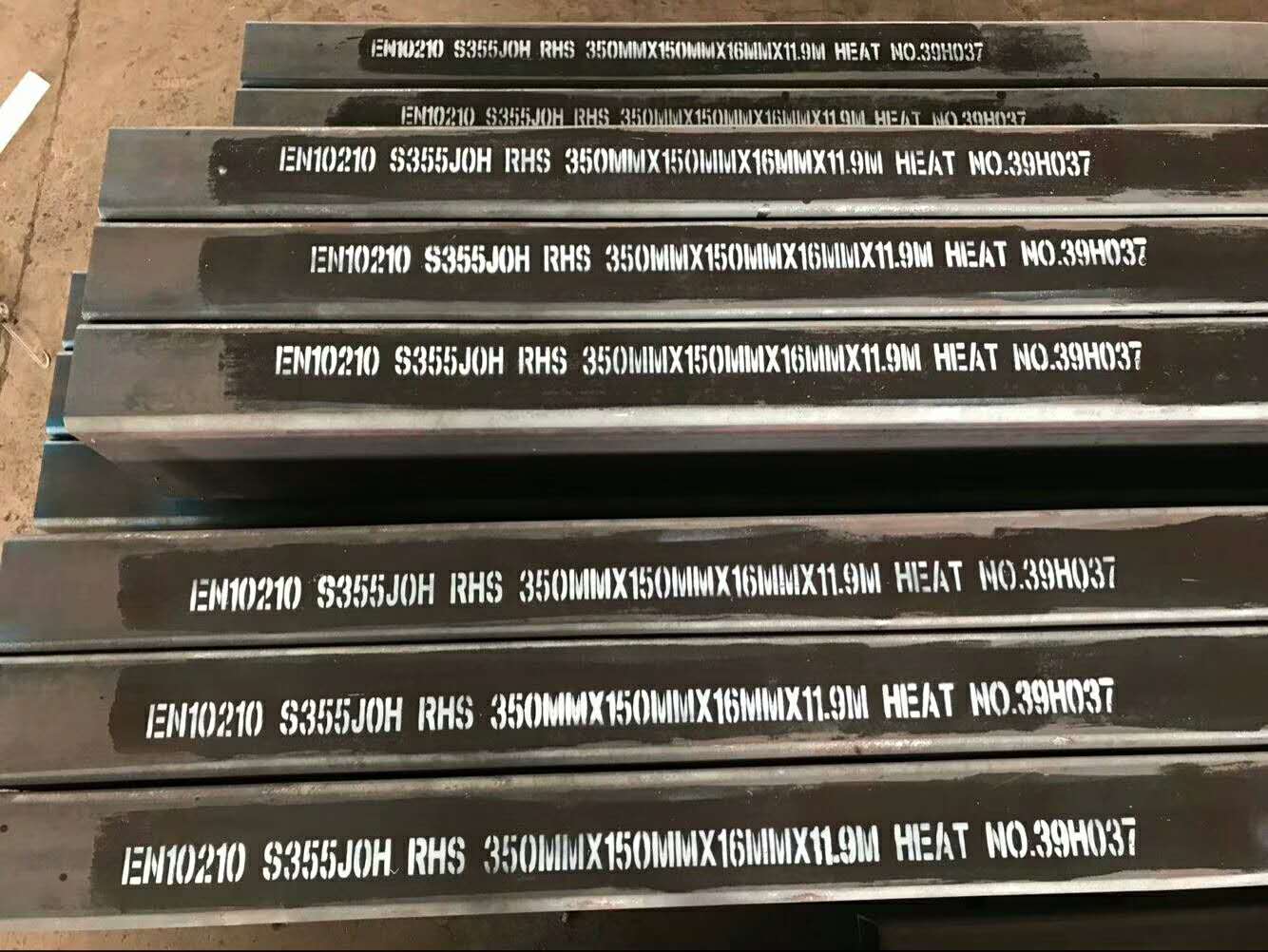

Q195, Q235, SS400, S235, STK400

3. Support principle:

1) The leading small conduit is a very effective auxiliary construction method for stabilizing the excavation face.

In the construction of weak and broken rock strata, the advanced small conduit plays a role in strengthening the

loose rock stratum. After grouting, the stability of the loose and weak surrounding rock is enhanced, which is beneficial

to the stability of the surrounding rock after the excavation and the completion of the initial support period. , so that the

surrounding rock will not be destabilized and damaged until it collapses.

2) The advanced small pipe grouting is suitable for the weak surrounding rock of the tunnel arch, loose, uncohesive soil layer,

sand layer with poor self-stabilizing ability and gravel (pebble) stone level broken rock layer.

3 ) The condition and stability of the surrounding rock can be changed by grouting through the advanced small conduit.

After the grouting is injected into the weak or loose formation or the fractures of the water-bearing broken surrounding rock,

it can be in close contact with and solidify. The slurry replaces the moisture and air between the soil particles and in the rock

fissures by filling, splitting, etc., and then occupies its position. , The consolidated body with high strength and good waterproof

performance greatly improves the loose and broken surrounding rock. .

4. Parameter:

The parameters for the construction of the advanced small conduit should be determined according to the boundary geological

conditions of the surrounding rock, the condition of the surrounding rock, the form of the supporting structure and the size of the

tunnel section. Generally, the construction of advanced small conduits is set along the excavation contour line within a range of 120 degrees.

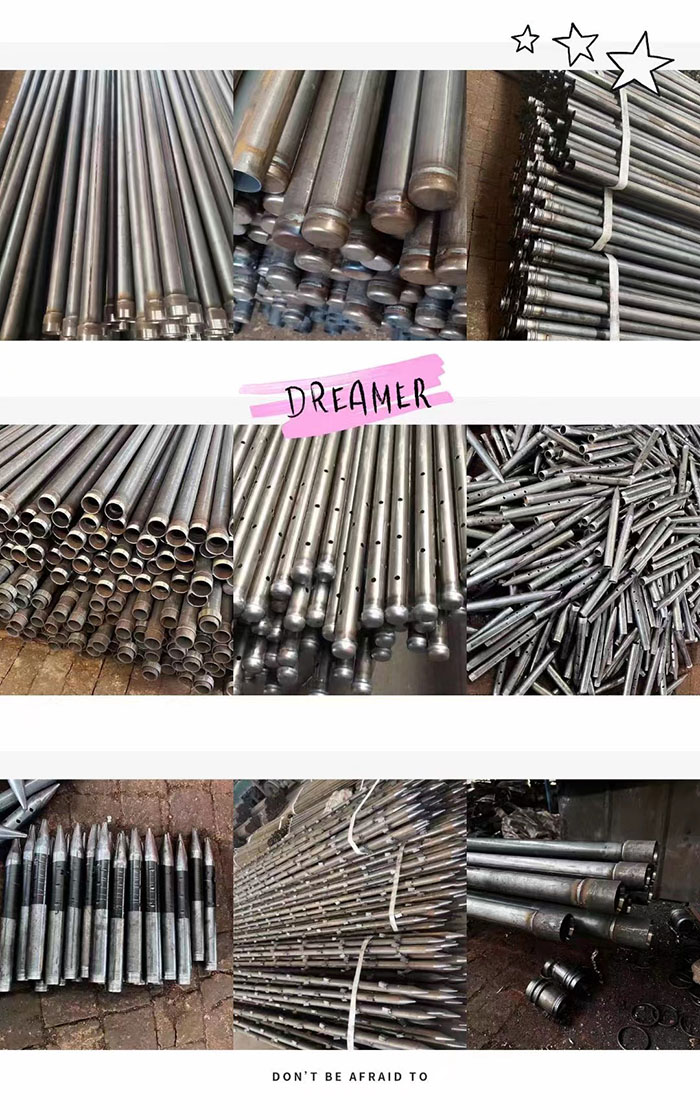

Under normal circumstances: the length of the small conduit L = the height of the upper step + 2m. Small catheter diameter: 38-50mm.

The front section of the small conduit is made into a cone shape with a length of about 10cm, and a steel hoop with a diameter of 6~8mm is welded at the tail end.

The extrapolation angle is generally controlled at 10 degrees to 15 degrees. The grouting pressure is controlled at about 2MP.

The slurry diffusion radius is generally 0.5m. The grouting speed is controlled at 50-100L/MIN. The overlapping length of each circulating small conduit is controlled within 1m.

5. Producing:

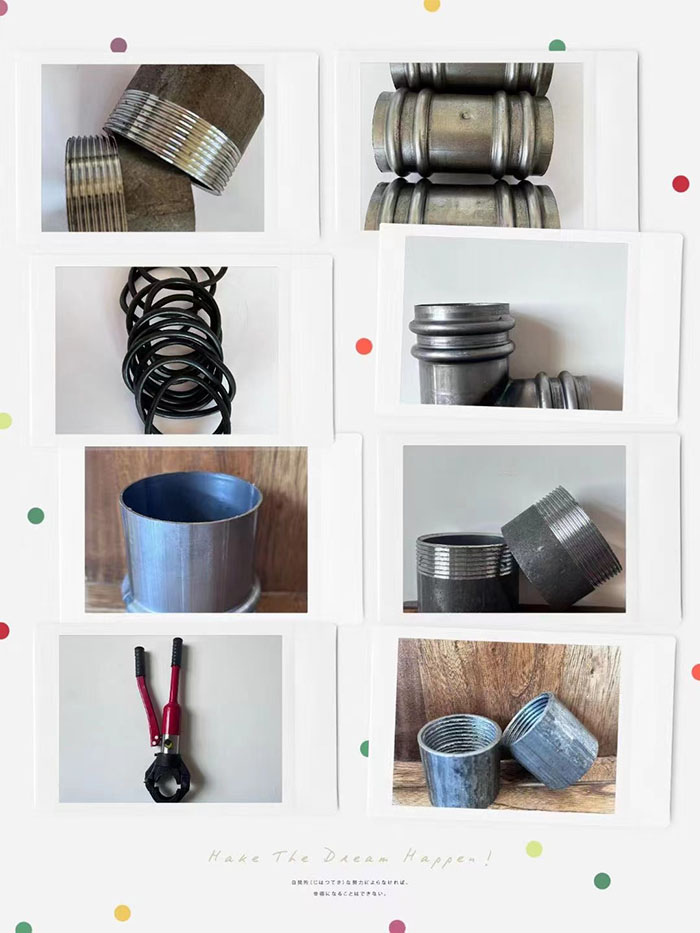

1) Generally, it is made of welded or seamless steel pipes with a diameter of 38~50mm.

2) Make a cone shape about 10cm long at the front end of the small conduit, and weld a steel hoop with a diameter of 6~8mm at the tail end.

No holes are opened within 100cm from the rear end, and the remaining part is arranged with a 6mm diameter overflow hole in a plum blossom shape of 20~30cm.

6. Installation:

Lead-through or direct push-in method can be used.

1) Drill holes with an electric drill, the diameter of the hole is larger than 10-20mm of the diameter of the small conduit, and the depth of the hole depends on the length of the conduit.

2) If it is difficult to insert the catheter, use a pneumatic drill with jacking function to jack the casing.

3) Use a blower to blow out the debris in the hole.

4) The end of the small catheter is wrapped with cotton yarn, so that the small catheter is closely attached to the drilled hole, and the empty port is blocked with cotton yarn.

5) After the small conduit is installed, it must be sealed with sprayed concrete within a certain range around it. The spray thickness is controlled at 5-8cm.

7. Picture: