SPA-H weathering ígwè oghere ngalaba, Corden Steel efere

1. Nkọwa dị mfe:

SPA-Higwe ihu igwe, nke a makwaara dị ka igwe na-eguzogide corrosion nke ikuku, na-ezo aka n'ụdị dị ala.alloyígwè dị elu

nwere obere ihe ndị na-emepụta ihe, ọnụ ala dị ala, na ezigbo nguzogide corrosion na ikuku. Isi alloying

ọcha bụ Cu, P, Cr, Ni, Si, Mn, V, RE, wdg N'oge ojiji nke weathering ígwè, a ok na ike mmasị ihe nkiri nchebe nke

ngwaahịa corrosion ga-eji nwayọọ nwayọọ na-etolite n'elu iji gbochie ikuku oxygen, mmiri na mgbasa ozi ndị ọzọ na-emerụ emerụ na ikuku

na-eme ka mkpụrụ ahụ dịkwuo njọ, nke mere na ọnụ ọgụgụ corrosion na-ebelata nke ukwuu ma e jiri ya tụnyere carbon ígwè. . N'ihi ike ya dị elu na

ọnụ ahịa ezi uche dị na ya, ọnụ ahịa mmepụta dị ala karịa igwe anaghị agba nchara. SPA-H ọkọlọtọ ọkọlọtọ bụ: JISG3125-2015.

2. Ngwakọta kemịkalụ:

| Ọkwa | Ngwakọta kemịkalụ (%) | |||||||

| C | Si | Mn | P | S | Cu | Cr | Ni | |

| SPA-H | ≤0.12 | 0.2-0.75 | ≤0.60 | 0.07-0.15 | ≤0.035 | 0.25-0.55 | 0.30-1.25 | ≤0.65 |

| Q235NH | ≤0.13 | 0.1-0.4 | 0.2-0.6 | ≤0.030 | ≤0.030 | 0.25-0.55 | 0.4-0.8 | ≤0.65 |

| Q355NH | ≤0.16 | 0.5 | 0.5-1.5 | ≤0.030 | ≤0.030 | 0.25-0.55 | 0.4-0.8 | ≤0.65 |

| Q450NQR1 | ≤0.12 | 0.4 | 0.7-1.5 | ≤0.02 | ≤0.08 | 0.25-0.45 | 0.4-0.9 | 0.05-0.4 |

3. Mechanical Njirimara

| Ọkwa | Ngwongwo igwe | ||

| Ike Mpụta (N/mm2)/(Mpa) | Ike Tensile (N/mm2)/(Mpa) | Mgbatị (%) | |

| SPA-H | 355 | 490 | ≥22 |

| Q235NH | ≥235 | 360-510 | ≥23 |

| Q355NH | 355 | 490-630 | ≥20 |

| Q450NQR1 | 345 | 470-630 | ≥21 |

4. Ngwa:

1) SPA-H bụ igwe ihu igwe maka nhazi akpa, ịkpụ na ịgbado ọkụ. A na-ejikarị SPA-H eme ihe maka arịa ụgbọ mmiri,

àkwà mmiri ígwè, ụgbọ mmiri na tankị iji gbochie corrosion ikuku.

2) A na-ejikarị SPA-H ihu igwe na-emepụta ihe. Ụlọ ọrụ ụgbọ njem akpa nwere akụkọ ihe mere eme karịa

Afọ 50 n'ụwa. Afọ 30 gara aga, ụgbọ njem akpa nke obodo m ka tọgbọrọ chakoo. Kemgbe mgbanwe na mmeghe, obodo m

Ịrụ ọdụ ụgbọ mmiri na njem ụgbọ mmiri ka na-aga n'ihu na-etolite. Karịsịa n'ime afọ ndị na-adịbeghị anya, mba ụwa chere ihu

ọnọdụ nke “otu akpa siri ike ịchọta.

5. ụkpụrụ nguzogide corrosion:

Mgbe ígwè na-ekpuchi ìhè anyanwụ na ifufe, nguzogide corrosion ya dị mkpa karịsịa. Mgbe etinyere phosphorus, ọla kọpa, chromium,

nickel na ihe ndị ọzọ na-achọpụta na ígwè, a ga-emepụta ihe nkiri nchebe siri ike na nke siri ike n'elu ihe ọla kọpa, nke

nwere ike ịrụ ọrụ nchebe ụfọdụ.

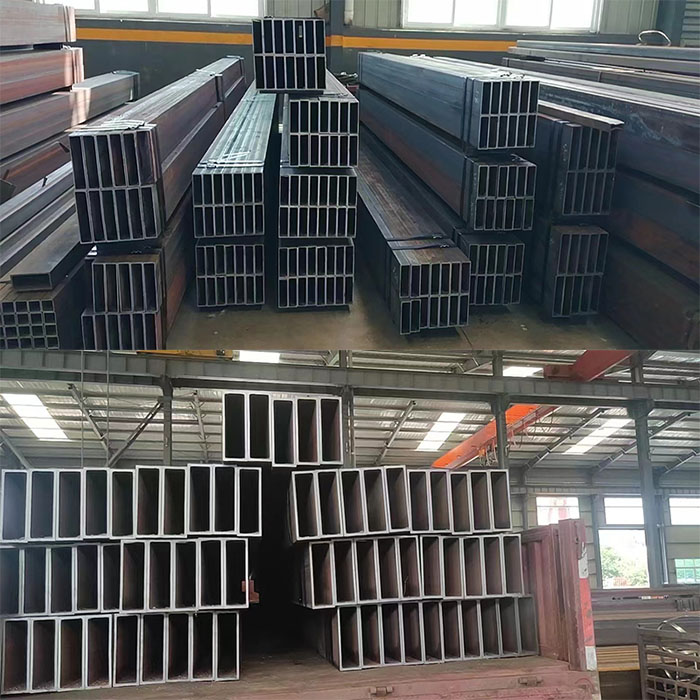

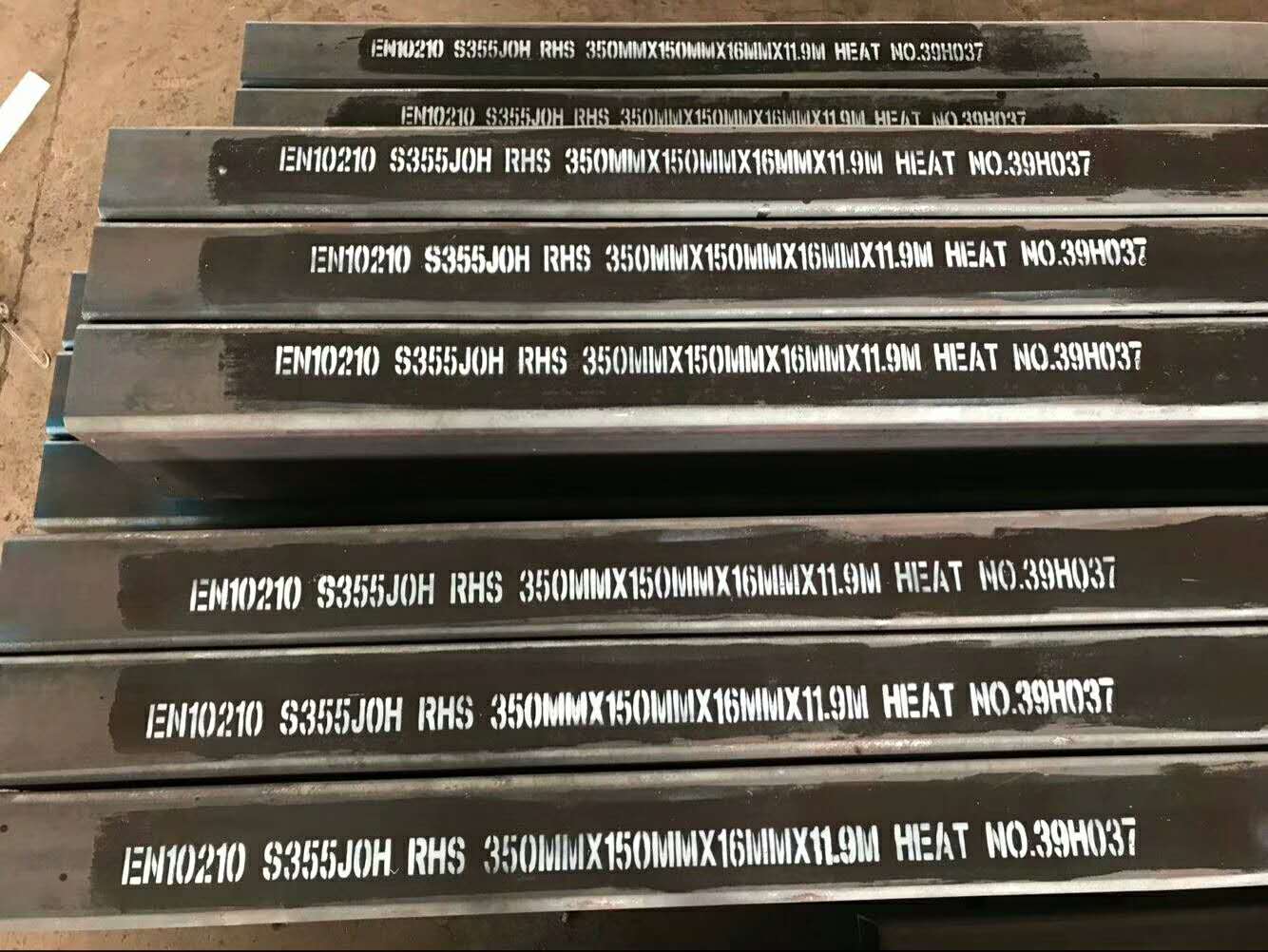

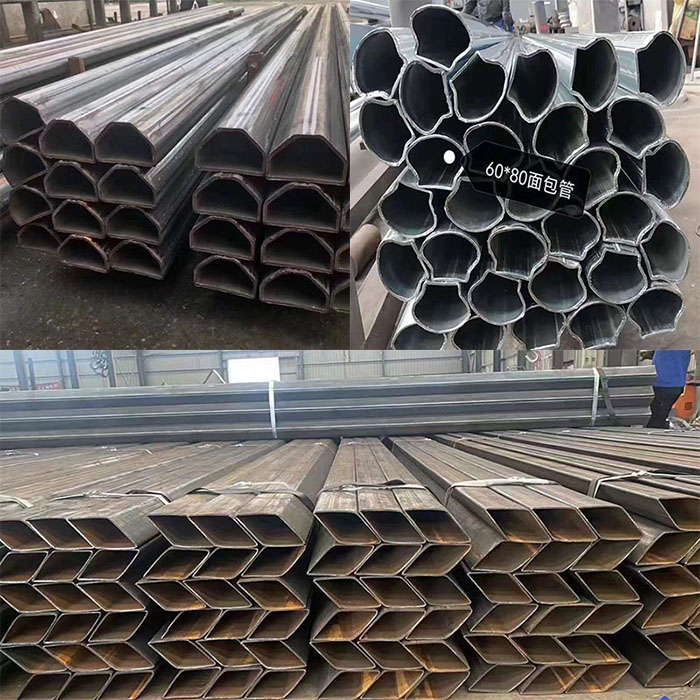

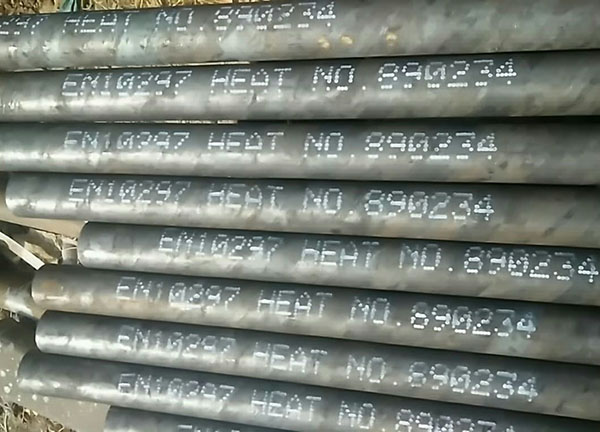

6. Foto:

7. Nbufe na ibu ihe akpa:

8. ngwugwu:

9. Ọkwa agbakwunyere (efere igwe):

B480GNQR,Q450NQR1,09CuPCrNi-A,SPA-H,Q550NQR1,09CUP,COR-TEN,cortenA,corten-B;05CuPCrNi B450NQ B800

Q235NH,Q295NH,Q295GNHJ,Q295GNH,Q345GNHJ,Q345GNHLJ,Q345GNH,Q310GNHJ,Q310GNHJ,Q310GNHLJ,Q35NHJ,Q35NH

集装箱板Q295GNHJ,Q345GNHLJ,Q345GNHJ;

焊接结构用耐候钢 16CuCr、12MnCuCr、15MnCuCr、15MnCuCr—QT;16MnR(HIC),08Cu,16MnCu,St34-3MnCu , Cor-TenB,

10CrMoAL, 16CuCr,12MnCuCr, 15MnCuCr,15MnCuCr-QT, 09CuPCrNi, SMA400(AW,BW,CW),A588,A570, SMA400(AP,BP,CP),(AP,BP,CP),SMA490

SMA490 (AP, BP, CP), SMA570W, SMA570P, Fe235W, Fe355W, WR50B, WR50C, Q345R (HIC), Q235NH (16CuCr), Q275NH, 12MnCuCr,Q35MnHnC,

Q460NH,15MnCuCr-QT.