700 × 300 H beam Q235B le Q345B beam, ke beha sebopeho sa tšepe Universal Column

1. Taelo e bonolo:

H-beam ke mofuta oa karolo ea moruo le karolo e sebetsang hantle haholo e nang le kabo e ntlafalitsoeng ea libaka tse fapaneng.

karo-karolelano e utloahalang ho feta boima ba 'mele. E reheletsoe ka karolo ea eona e tšoana le tlhaku ea Senyesemane "H". Kaha likarolo tsohle tsa

H-beam e hlophisitsoe ka li-angles tse nepahetseng, B-beam e na le melemo ea ho hanyetsa ho kobeha, kaho e bonolo,

ho boloka litšenyehelo le boima bo bobebe ka mahlakoreng 'ohle,' me e se e sebelisoa haholo.

2. Sebopeho sa Lik'hemik'hale

| Kereiti | Sebopeho sa Lik'hemik'hale (%) | ||||

| C | Si | Mn | P | S | |

| Q235B | ≤0.20 | ≤0.35 | ≤1.40 | ≤0.045 | ≤0.045 |

| Q345B | ≤0.20 | ≤0.50 | ≤1.70 | ≤0.035 | ≤0.035 |

| Q345C | ≤0.20 | ≤0.50 | ≤1.70 | ≤0.035 | ≤0.030 |

| Q345D | ≤0.18 | ≤0.50 | ≤1.70 | ≤0.035 | ≤0.025 |

3. Thepa ea Mechini

| Kereiti | Thepa ea Mechini | ||

| Matla a Kotulo (N/mm2)/(Mpa) | Matla a ho Tsitsisa (N/mm2)/(Mpa) | Elongtation (%) | |

| Q235B | ≥235 | 370-500 | ≥26 |

| Q345B | 345 | 470-630 | ≥20 |

| Q345C | 345 | 470-630 | ≥21 |

| Q345D | 345 | 470-630 | ≥21 |

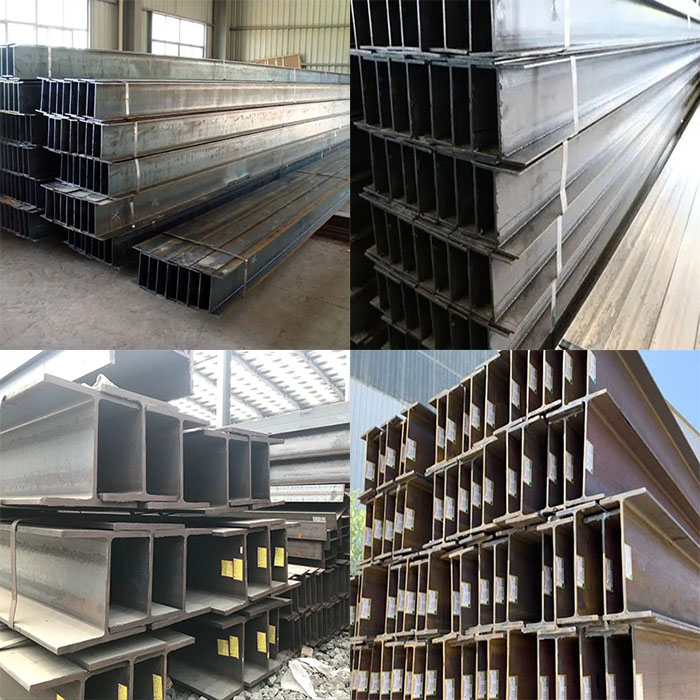

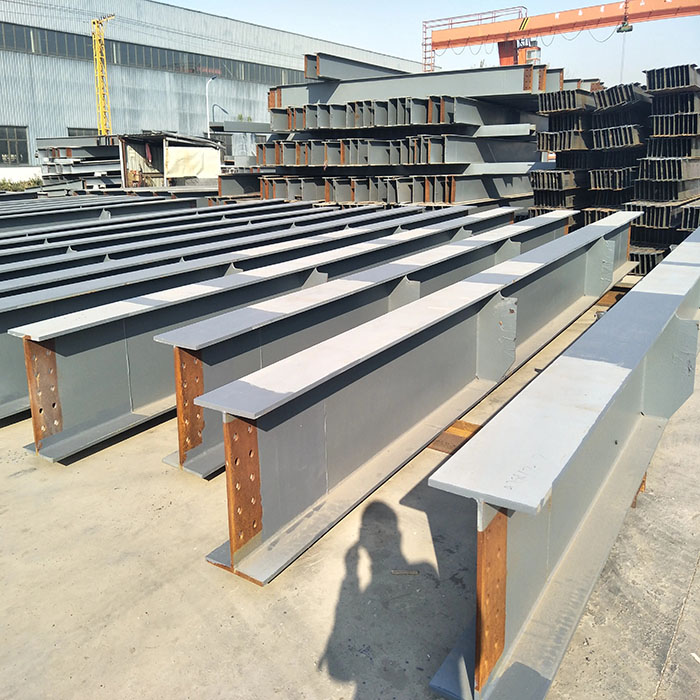

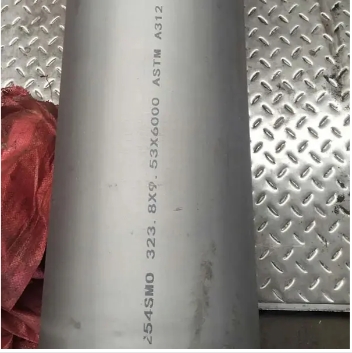

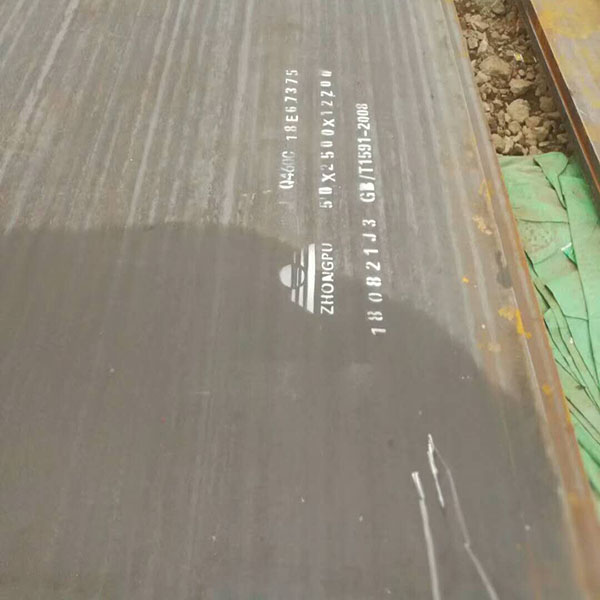

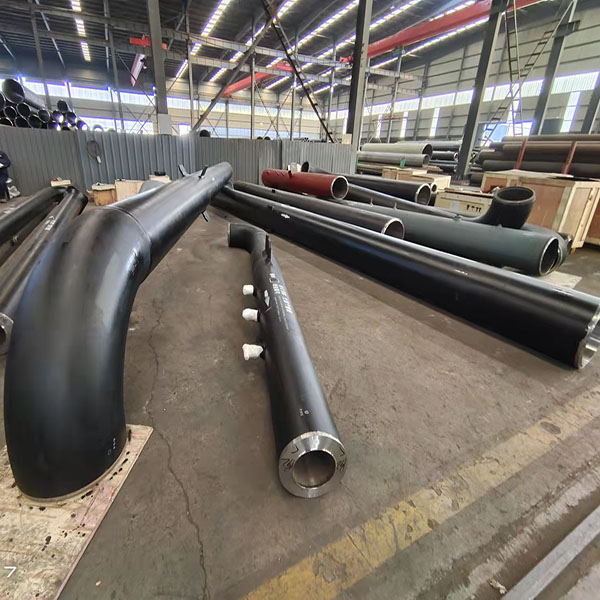

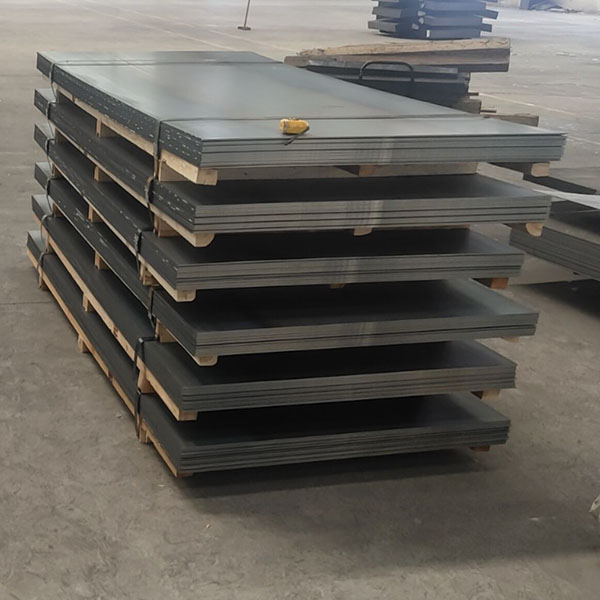

4. Pontšo ea Litšoantšo:

5. Kalafo e eketsehileng:

6. High Frequence Welded H beam:

High-frequency current e sebelisetsoa ho futhumatsa bokaholimo ba tšepe sebakeng sa heno, 'me e cheselitsoe tlas'a ketso ea matla a kantle, ntle le

terata leha e le efe ea tjheseletsa kapa flux, 'me e ka tsoela pele ho hlahisoa ka bongata bo boholo.

1) Mefuta e mengata ea litlhaloso (boholo ba karolo). Bophahamo, marang-rang, botenya ba flange le bophara ba flange bo ka khethoa ho latela moreki

litlhoko tsa tšepe poleiti tjheseletsa. E ka sebelisoa e le mefuta e meng ntle le maemo a hot-rolled H-beam.

2) Khetha mefuta e sa tšoaneng ea tšepe. Mabala a H-rolled a chesang haholo ke Q235B le Q345B. Ha lihlopha tse nyenyane tsa lihlopha tse khethehileng tsa tšepe li

tse hlokahalang, semela sa tlhahiso ha se khone ho li hlahisa. Welding e ka khetha poleiti ea tšepe ha ho hlokahala.

3) Sehlahisoa se na le ho nepahala ho phahameng le boleng bo botle ba holim'a metsi. Ka lebaka la boleng bo holimo le boleng bo holimo ba sehlahisoa sa tšepe,

ho nepahala ha H ka mor'a ho tjheseletsa le hona ho phahame mme boleng ba bokahodimo le bona bo botle. Ho kheloha botenya ba lipoleiti tsa tšepe (tse sebelisetsoang ho tjheseletsa maballo a H)

ka kakaretso ke karolo ea leshome ea millimeter ho ea ho tse seng kae tsa leshome tsa millimeter, athe botenya ba maballo a H-rolled a chesang ke karolo ea leshome ea

millimeter ho isa ho 1 millimeter, e leng phapang e ka bang makhetlo a 10.

4) Ts'ebetso e tsitsitseng le tlhophiso e ntle ea ka hare. Ho tloha ka tlhahiso ea lipoleiti tsa tšepe ho tloha ho qhibiliha ho ea ho ho lahla ho tsoelang pele ho ea ho roala ke

e phahameng ho feta ea li-hot-rolled H-beams ) lipontšo li tšepahala ebile li tsitsitse.

5) Ho bonolo ho ba le bofokoli ba ho chesella. Le hoja ho na le melemo e mengata e boletsoeng ka holimo, ka lebaka la ho thehoa ha welding, ho na le masala a tjheseletsa

khatello ea mocheso sebakeng sa welding, sebopeho sa sebaka sa welding se fapane, 'me ho na le khatello ea maikutlo, e atisang ho ba le mefokolo ea welding.

Ka ntlafatso e tsoelang pele ea boemo ba tjheseletsa le boemo ba phekolo ea mocheso, mefokolo ena e fokotseha butle-butle. Kajeno, boleng bo phahameng welded

Maballo a H a sebelisitsoe mafapheng a fapaneng ho kenyelletsa indasteri ea sesole le sebaka sa sefofane.