700 × 300 H umqadi Q235B kunye Q345B umqadi, I beam Steel isakhiwo Universal Column

1. Umyalelo olula:

I-H-beam luhlobo lwecandelo loqoqosho kunye necandelo elisebenza ngokufanelekileyo elinokusasazwa kwendawo enqamlezileyo kunye

Umlinganiselo wamandla ukuya kubunzima obusengqiqweni. Ithiywe ngegama lecandelo layo iyafana nonobumba wesiNgesi “H”. Ekubeni zonke iindawo ze

I-H-beam icwangciswe kwii-engile ezichanekileyo, i-H-beam ineenzuzo zokugoba okunamandla, ulwakhiwo olulula,

ukonga iindleko kunye nobunzima obulula kuzo zonke iinkalo, kwaye isetyenziswe ngokubanzi.

2. Ukubunjwa kwemichiza

| IBanga | Ukwakheka kwemichiza (%) | ||||

| C | Si | Mn | P | S | |

| Q235B | ≤0.20 | ≤0.35 | ≤1.40 | ≤0.045 | ≤0.045 |

| Q345B | ≤0.20 | ≤0.50 | ≤1.70 | ≤0.035 | ≤0.035 |

| Q345C | ≤0.20 | ≤0.50 | ≤1.70 | ≤0.035 | ≤0.030 |

| Q345D | ≤0.18 | ≤0.50 | ≤1.70 | ≤0.035 | ≤0.025 |

3. IiPropati zoomatshini

| IBanga | IPropati yoomatshini | ||

| Amandla eSivuno (N/mm2)/(Mpa) | Amandla Okuqina (N/mm2)/(Mpa) | Ubude (%) | |

| Q235B | ≥235 | 370-500 | ≥26 |

| Q345B | 345 | 470-630 | ≥20 |

| Q345C | 345 | 470-630 | ≥21 |

| Q345D | 345 | 470-630 | ≥21 |

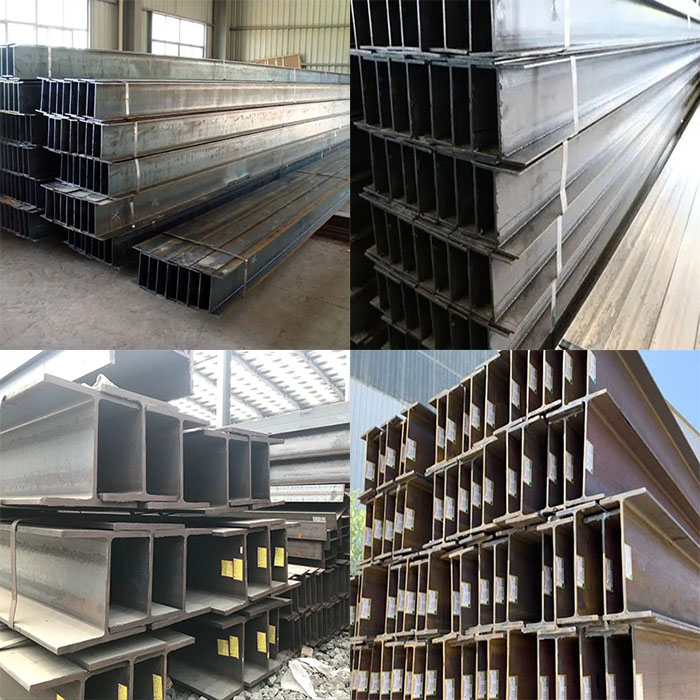

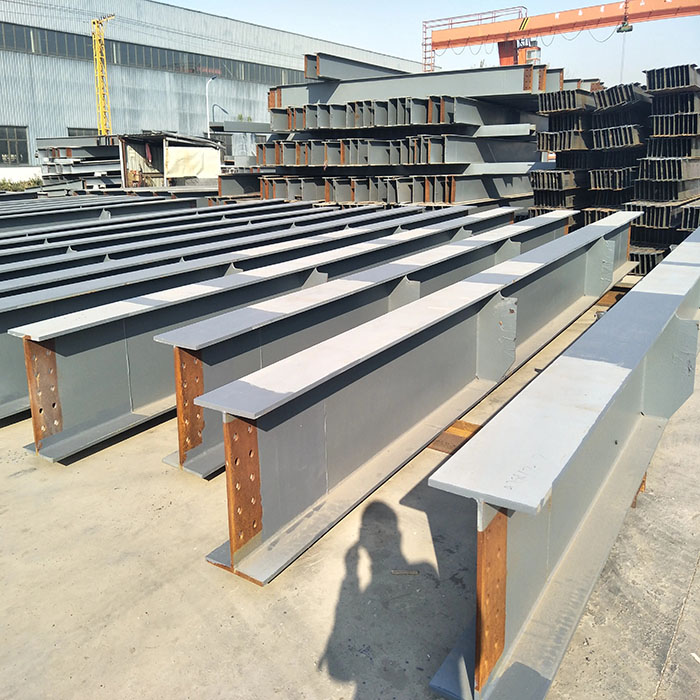

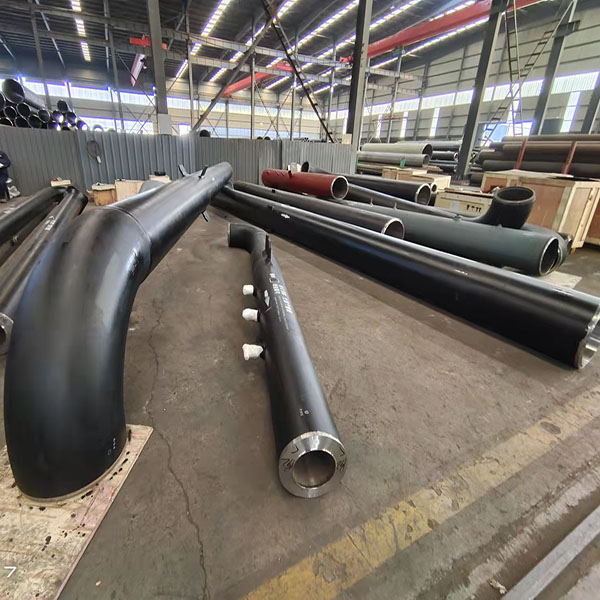

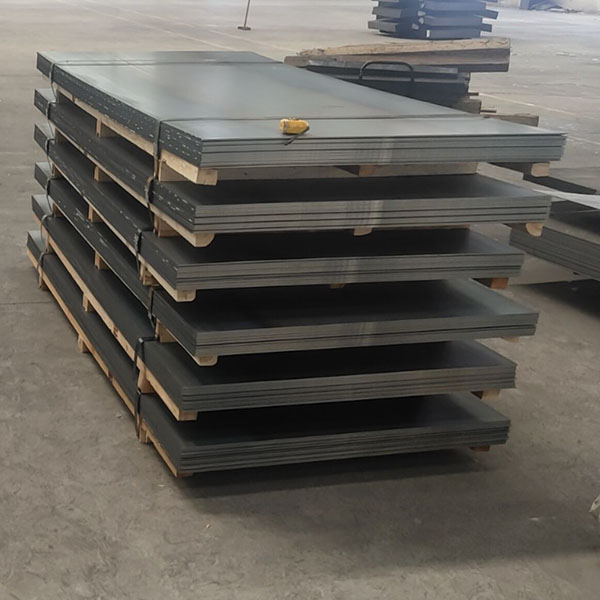

4. UMboniso weMifanekiso:

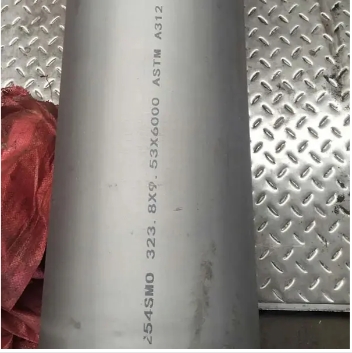

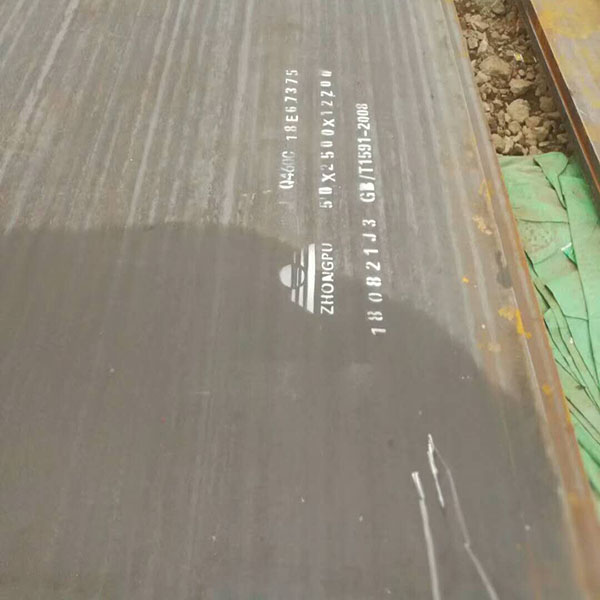

5. Unyango olongezelelweyo:

6. Umqa we-Welded H oPhezulu:

I-high-frequency current isetyenziselwa ukufudumeza indawo yentsimbi yendawo, kwaye idityaniswe phantsi kwesenzo samandla angaphandle, ngaphandle

naluphi na ucingo lwe-welding okanye i-flux, kwaye inokuveliswa ngokuqhubekayo ngobuninzi obukhulu.

1)Uluhlu olubanzi lweenkcukacha (ubungakanani becandelo). Ubude, iwebhu, ubukhulu be-flange kunye nobubanzi be-flange bunokukhethwa ngokomthengi

iimfuno zentsimbi ipleyiti welding. Ingasetyenziswa njengezinye iindidi ngaphandle komgangatho we-H-beam eshushu.

2) Khetha iintlobo ezahlukeneyo zetsimbi. Imiqadi ye-H eqengqelekayo ishushu ikakhulu yi-Q235B kunye ne-Q345B. Xa iibhetshi ezincinci zamabakala akhethekileyo ensimbi

ezifunekayo, isityalo semveliso asikwazi ukuzivelisa. I-Welding inokukhetha ipleyiti yentsimbi njengoko kufuneka.

I-3) Imveliso inokuchaneka okuphezulu kunye nomgangatho omhle womphezulu. Ngenxa yokuchaneka okuphezulu kunye nomgangatho olungileyo womphezulu wemveliso yeplate yentsimbi,

Ukuchaneka kwe-H emva kwe-welding kukwaphezulu kwaye umgangatho womphezulu nawo ulungile. Ukutenxa ubukhulu beepleyiti zentsimbi (ezisetyenziselwa ukuwelda imiqadi ye-H)

ngokuqhelekileyo zizishumi ezimbalwa zemilimitha ukuya kwisiqingatha seshumi semilimitha, ngelixa ukutenxa kobukhulu bemiqadi eqengqelekisiweyo eshushu zizishumi ezimbalwa zemitha.

imilimitha ukuya kwimilimitha e-1, ephantse ibe ngama-10 umahluko.

4) Ukusebenza okuzinzileyo kunye nolungelelwaniso olulungileyo lwangaphakathi. Ekubeni ukuveliswa kweepleyiti zentsimbi ukusuka kwi-smelting ukuya kwi-casting eqhubekayo ukuya kwi-rolling yi

eziphezulu kunezo ze-hot-rolled H-beams ) izikhombisi zithembekile kwaye zizinzile.

5) Kulula ukuba neziphene ze-welding. Nangona kukho iinzuzo ezininzi ezikhankanywe ngasentla, ngenxa yokubunjwa kwe-welding, kukho i-welding residual

uxinzelelo lwe-thermal kwindawo ye-welding, isakhiwo sendawo ye-welding sihluke, kwaye kukho uxinzelelo lwesakhiwo, olujongene neziphene ze-welding.

Ngokuphuculwa okuqhubekayo kwinqanaba le-welding kunye nenqanaba lonyango lokushisa, ezi zinto zingalunganga ziyancipha ngokuthe ngcembe. Namhlanje, umgangatho ophezulu welding

Imiqadi ye-H isetyenziswe kwiinkalo ezahlukeneyo ezibandakanya imboni yomkhosi kunye ne-aerospace.